Page 2 of 2

Re: Oil Leak

Posted: Mon Jan 19, 2015 6:34 pm

by c170b53

Dick wrote

Back in February of 1951 I went up to Downsview Canada, to pick up the first De Haviland Beaver the USAF bought for service testing. That's the way the factory wechanics dried up the oil leaks on the second hand P&W R-985 engines they had

That's the way we still do it (developer) today for oil and air leaks especially in the hot areas. And whack can its ?

I resemble that remark too

Re: Oil Leak

Posted: Mon Jan 19, 2015 6:42 pm

by hilltop170

blueldr wrote:I know of one owner that "staked" the plug in the IO-360 crankshaft using a center punch after heard about Richards problem. This was on a TCM IO-360 conversion using a fixed pitch prop.

Dick-

How was the plug staked?

Re: Oil Leak

Posted: Mon Jan 19, 2015 10:13 pm

by 170C

After spending an hour in a '48 Navion while the owner played with his iPad's HSI (boy that thing is heavy on the controls compared to our Cessna's) I pulled my spinner and the crankshaft plug is dry as ever. Must be the crankshaft seal. For O-300's is the seal one of the type that requires the prop to be removed to install it or is is a seal that can be installed with the prop on?

Re: Oil Leak

Posted: Mon Jan 19, 2015 11:51 pm

by GAHorn

If the seal is a "split" type, it can be installed with the prop in situ. The TCM Overhaul manual describes the procedure.

From the Ovhl manual: " Remove spring from new crankshaft oil seal. Twist seal, and pass it over the shaft race behind the prope~ler flange, with lip to rear. Coat seal lip and shaft race with Gredag #44. Pass the spring around the shaft, and hook the ends. Lift the spring progressively into the seal groove. ..."

Next, be certain the split in the seal is at least 20-degrees offset from the crankcase split. I recommend you pre-lube the seal inner surface with engine oil if you don't have "Gredag #44" to make certain it does not wear excessively during first start up.

Re: Oil Leak

Posted: Tue Jan 20, 2015 1:02 am

by blueldr

Richard,

The guy that had the staked plug was up at Johnson Creek and we got to discussing our inatallations. I also had a FP propon my airplane at that time. We discussed the problem you had with the plug and he told me he had read your comments and had staked it using a long center punch with an offset point. I didn't see the tool or the job. I had pulled the plug on mine and used locktite on it. Not much later I went to a CSprop and removed the plug.

I had oil on my windshield one time with my original C-145 engine. I found oil coming out of the spinner on the back side of the prop and thought "How in hell do you get a FP prop to leak oil". When I pulled the spinner, I found that the "freeze plug" in the front main journal had come out and the engine was breathing out through the hollow prop shaft.

Re: Oil Leak

Posted: Sat Feb 06, 2021 6:14 pm

by mmcmillan2

For the C-145 crank seal replacement, is this a one hour job for most mechanics? Just need to pull the cowl halves off? I understand that it is a split style so the prop can stay in place. I’m getting a light oil mist on the windshield after a long flight, along with a small amount of oil on the leading edge of the cowl opening near spinner. The seal area does look wet, so I was going to order the seal (530917) for my mechanic to install after he inspects the engine. Are there any other parts that will be needed for the swap?

Re: Oil Leak

Posted: Sun Feb 07, 2021 7:45 am

by GAHorn

mmcmillan2 wrote:For the C-145 crank seal replacement, is this a one hour job for most mechanics? Just need to pull the cowl halves off? I understand that it is a split style so the prop can stay in place. I’m getting a light oil mist on the windshield after a long flight, along with a small amount of oil on the leading edge of the cowl opening near spinner. The seal area does look wet, so I was going to order the seal (530917) for my mechanic to install after he inspects the engine. Are there any other parts that will be needed for the swap?

TCM SB M76-4 (in the MX Library) provides the instructions to replace the crankshaft seal:

viewtopic.php?f=29&t=8201

You’ll need some emery-cloth to put the “swirl” on the crankshaft as described in the Service Bulletin.

Re: Oil Leak

Posted: Sat Apr 06, 2024 2:39 pm

by Larry E

Here's a question for the engine gurus of this wonderful forum:

3 years ago at 1663 hours, my C-145-2H was opened for a new cam, bearings, and 6 new Superior cylinders (plus a lot of other system upgrades, etc.) by a local shop with top notch quality work. It has been running flawlessly in the subsequent 90 hours. I just pulled the prop for it's 5 year inspection and this is what I found:

The plane has not flown since November 2023 and first flight this year was 3 weeks ago.During the past 2 hours of flight time a very thin, small streak of oil has appeared on the front face of one prop blade. There does not appear to be any oil on the back of the prop so I'm pretty sure the seal is OK

My question is regarding the Continental Engine IPC. The exploded diagram depicts an O-ring between the plug and retaining ring. This is for the C-145-2H, NOT for the -2 or some of the O-300 variants. This engine now has no visible O-ring, so I'm wondering if the IPC diagram is accurate?? Or maybe I'm reading it wrong.

Does anyone have experience with the C-145-2H crankshaft plug? And leak repair?

Earlier posts on this thread suggest there have been problems with the O-360 crankshaft substitution.

There is no record of such a change in this engine, and I also wonder if there is a way to identify which crankshaft is installed here...

My mechanic says he's investigating but I thought there's probably a lot more expertise in our association.

I'd really appreciate any ideas, experience, advice, etc.

Larry

Re: Oil Leak

Posted: Sat Apr 06, 2024 9:38 pm

by n2582d

Larry,

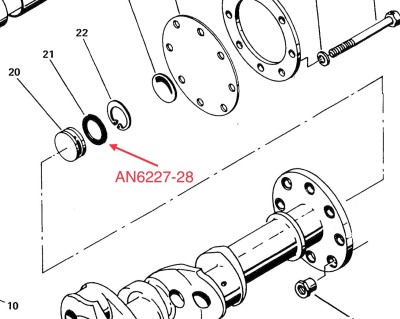

I also have an O-300B engine. The plug which is retained by the snap ring has a groove in it.

- AN6227-28

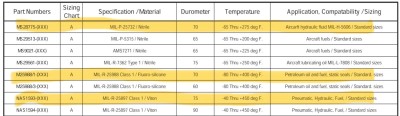

The AN6227-28 o-ring fits in this groove. AN6227-28 is an obsolete part number and is replaced by MS28775-325. Looking at the chart in

Genuine Aircraft Hardware’s catalog, one might consider using an MS25988/1-325 o-ring as that is listed as being compatible with engine oil.

- Click to Enlarge

I can’t recall now whether the lever on the front left side of the engine should be wired in the up or down position but that should be checked to prevent oil flowing to the prop hub.

Re: Oil Leak

Posted: Sun Apr 07, 2024 2:29 pm

by Larry E

Thanks Gary.

The "lever" is wired in the up position (both before and after the engine work).

It makes sense that the O-ring goes around the plug, and I assume the overhauler must have installed one. Perhaps it has failed. I'll order one of these as a "just-in-case".

Or maybe the plug is the wrong type?? The IPC seems to imply there is more than one type of plug. Which might be important if an unknown crankshaft has been used. Does anyone know how to get that plug out without damaging it?

Larry

Re: Oil Leak

Posted: Sun Apr 07, 2024 5:06 pm

by n2582d

There are two options for plugs; what you have — p/n 25149, or a hubbard plug — p/n 24770. As you can see in the last column of the IPC, p/n 25149 is useable on code C and E which translates to the C145-2H and the O-300B engines. Remove the snap ring and pull on the plug center nub with a pliers to remove the plug. Should come right out.

Re: Oil Leak

Posted: Sun Apr 07, 2024 8:43 pm

by Bruce Fenstermacher

Remove the snap ring, pull the plug, clean out any sludge you find behind the plug. Replace the o-ring. Put some motor oil on it. Replace the plug and snap ring. Your good.

Re: Oil Leak

Posted: Mon Apr 08, 2024 6:35 am

by n2582d

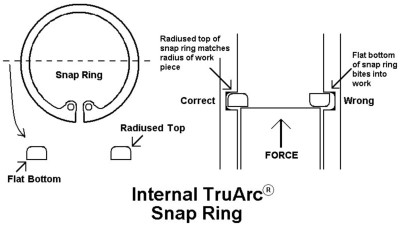

I was going to say make sure and install the snap ring correctly as it’s easy to install them backwards. I’m embarrassed to say that I was about to give the wrong advice. Here’s the right way according to

this website:

- Click to Enlarge

Re: Oil Leak

Posted: Mon Apr 08, 2024 1:14 pm

by Larry E

Gary and Bruce.

Thank you for your replys.

Larry

Snap Ring Orientation

Posted: Wed Apr 24, 2024 4:59 pm

by n2582d

Apologies in advance for the thread drift.

My previous entry about snap ring orientation should not be used when installing the crankshaft counterweight pins. The overhaul manual specifies that the snap ring be installed “with the flat or rough side to the outside.” Similar instructions are shown on Mandatory Service Bulletin MSB 23-01A: